The Mallett Performance Cars team returned to SEMA this year to promote the launch of our 2015+ Chevy Colorado/GMC Canyon supercharger system. We showcased this highly-modified 2015 Colorado with our friends from Magnuson in their booth this year.

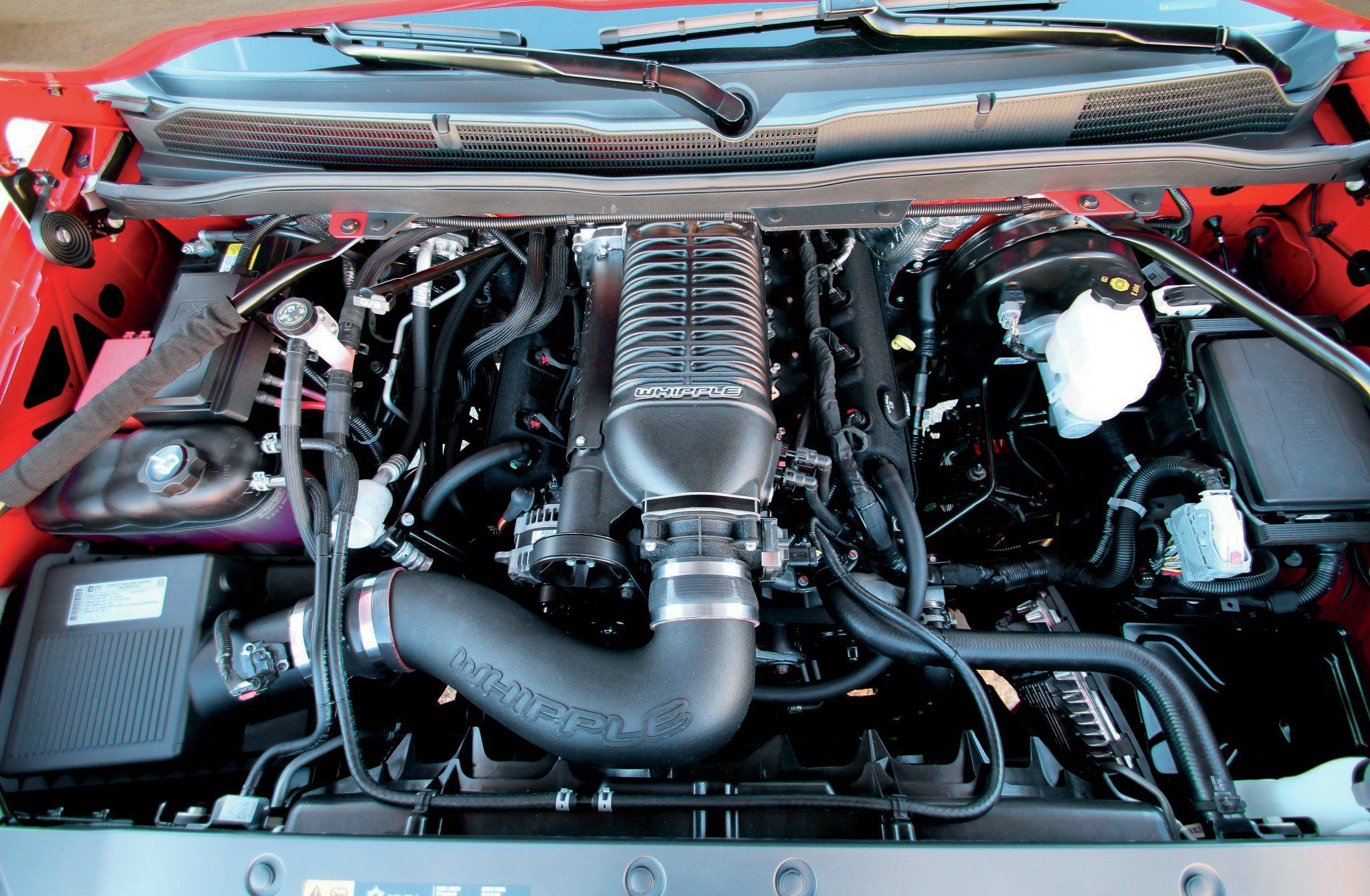

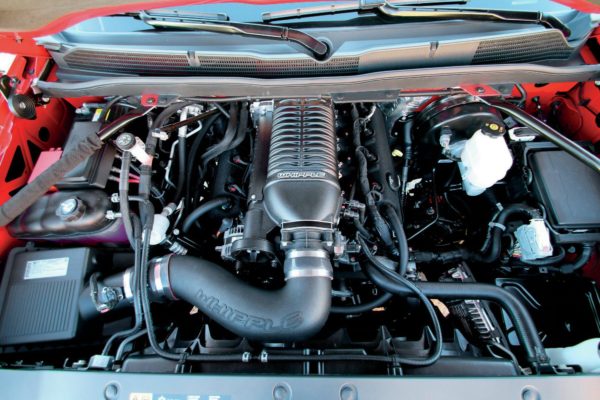

We swapped the stock engine for a 3.6L V6 from a 2016 Cadillac ATSV. This engine is already built for boost.

The engine features a forged crank, titanium connecting rods, and forged pistons.

Bolted to the top is a Mallett Colorado Intercooled Supercharger Manifold assembly complete with a Magnuson 1.9L supercharger, custom 64mm C&R intercooler, custom CNC-machined upper and lower 8-rib pulleys, front engine idler pulley, tensioner mounting plate, drill-less mounted aluminum intercooler tank and water pump, and C&R heat exchange.

We used a C7 LT1 throttle body to open up the intake side and crafted a custom air intake box. It’s outfitted with a highly custom-fabbed, high-flowing true dual exhaust to polish off the performance mods. This mean machine was fueled with 109 race fuel.

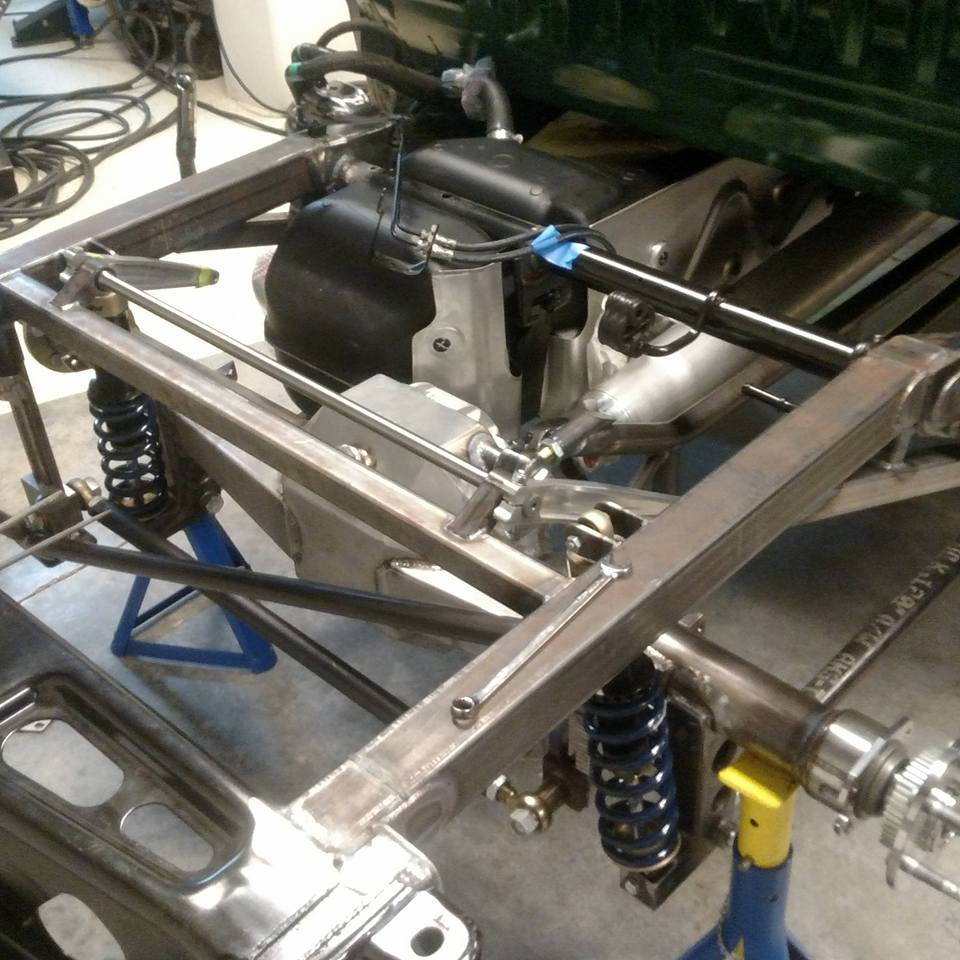

Behind the V6 is a modified stock transmission that turns a narrowed Moser nine-inch rear-end with WaveTrac and aluminum center section. We added Forgeline custom MS3C concave wheels-19x9x.5 front and 20×13 rear, wrapped in rear 315/35/20 BF Goodrich G-force Rivals.

A lot of custom work was put into the chassis and suspension for drivability and stability. We adjusted the ride height to lower the center of gravity. Custom drop spindles were fabricated with custom lower control arms up front. Custom Penske coilover shocks were also installed.

The rear frame section was raised and narrowed, and a custom three-link ladder system with center frame crossbar and driveline hoops were fabricated and welded in.

We installed a custom rear sway bar and adjustable panhard bar were installed to fine tune the truck’s balance. With the size of the rear tires we tubbed the truck bed four-and-a-half inches wider on each side.

The brakes got an overhaul to make sure we could stop this beast. A big thank you to Mike Mecina and Danni Jacobs of Brembo brakes. They came to the rescue with custom Brembo brakes, 6 piston front calipers and 4-piston rear brake calipers with floating rotors.

On the exterior, we removed all the plastic trim, added a custom front grille, and a custom fascia. We added a custom carbon front spoiler for an aggressive look.

Contrast stitching was added to the seats, and Water Buffalo seat inserts. Some trim panels were hydro dripped, and a six Kicker speaker with sub stereo add to the pleasure of driving.

A very sincere thanks to all of our sponsors, vendors, and team members who helped make this vision a reality.

Here is a complete list of modifications:

Powertrain and Performance

- 2016 Cadillac ATSV 3.6L V6

- Engine Block

- Forged Crank

- Titanium Connecting Rods

- Forged Pistons

- Mallett Colorado Intercooled Supercharger Manifold Assembly

- CNC Machined Manifold/Intercooler Base and Cover Plate

- Magnuson 1.9L Supercharger

- Custom 64mm High Efficiency C & R Intercooler

- Custom CNC Machined Upper and Lower 8-Rib Pulleys

- Custom CNC Machined Front Engine Idler Pulley and Tensioner Mounting Plate

- Custom, Drill-Less Mounting, Aluminum Intercooler Tank

- Custom Fabricated, Drill-Less, Frame Mounted Intercooler Water Pump

- Custom C & R Heat Exchanger

- C7 LT1 Throttle Body

- Custom Air Intake Box

- Custom High Flow Dual Exhaust

- Custom Dyno Tuned 750+ Horespower

- Suspension

- Penske Coil-over Shocks

- Custom Drop Spindles

- Custom Lower Control Arms

- Narrowed Moser 9” Differential with WaveTrac and Aluminum Center Section

- Raised and Narrowed Rear Frame Section

- Custom 3-Link Ladder System with Center Frame Cross-Bar and Driveline Hoops

- Custom Rear Swaybar and Adjustable Panhard Bar

- Brembo 6-Piston Front Brake Calipers and 4-Piston Rear Brake Calipers w/Floating Rotors

- Forgeline Custom MS3C Concave Wheels – 9.5 x 19 Fronts, 13 x 20 Rears

- BF Goodrich G-Force Rival Tires – 285/35ZR 19 Front, 315/35ZR 20 Rear

Interior and Exterior

- Exterior

- Tubbed Truck Bed with Rear Roll Pan and Lexan Spoiler

- Smoothed Bed Top Rails with All Plastic Trim Removed

- Custom Front Grill

- Custom Front Fascia

- New Mallett Colorado Front Splitter

- New Hood with Air Extractor

- Interior

- Contrast Stitching Seats with Water Buffalo Leather Seat Inserts and Grommets

- Formed Aluminum Door Panel Inserts Wrapped in Water Buffalo Leather with Contrast Stitching and Grommets

- Formed Aluminum Dash Panel Top Wrapped in Water Buffalo Leather with Contrast Stitching and Grommets

- Custom Dash Top Gauge Pod Wrapped in Water Buffalo Leather and Contrast Stitching

- Custom Center Console Arm Rest Wrapped in Water Buffalo Leather, Contrast Stitching and Grommets

- Hydro Dipped Plastic Trim Panels

- Kicker Speakers (6) and Sub-Woofer Enclosure